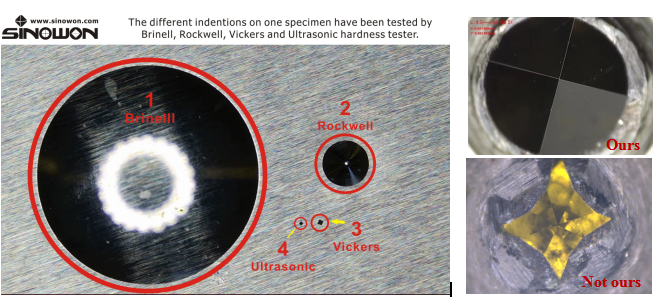

Why most of people think it is non-destructive about the hardness testing of UCI (Ultrasonic contact impedance) method, it will be easier to get it after checking the photo about different testing identifications on one same specimen penetrated by Brinell, Rockwell, Vickers and Ultrasonic hardness tester made by Sinowon laboratory.

Compare to the indention of Rockwell indention, the UCI indention is too tiny to observe by human eyes, due to the diagonal size is around 15um, so most of the customers think it is a non-destructive method. In addition, the testing speed is faster 0-20 times than Rockwell too, it is very useful to use at the workshop to filter the workpieces with wrong heat treatment.

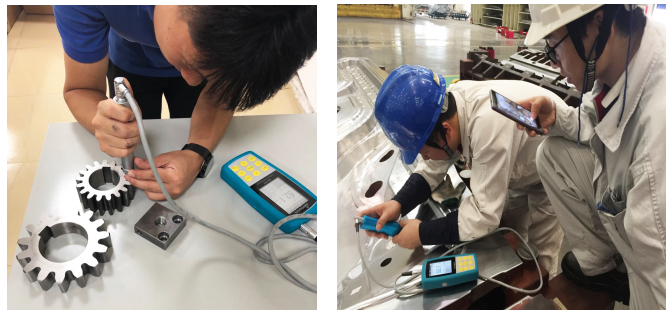

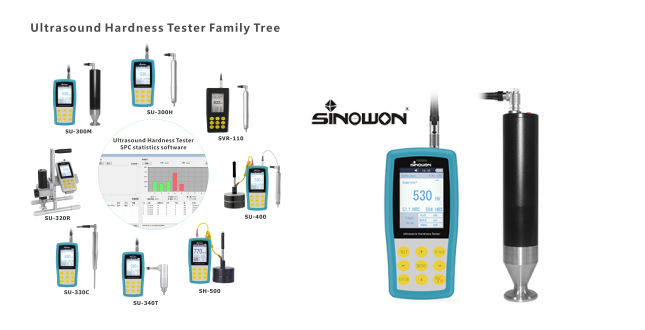

Sinowon is one of key manufactures of ultrasonic hardness tester in the world since year 2010 with ISO9001: 2015 verification, our UCI durometer SU-100, SU-300, SU-400 series have been applicated to test the hardness precise automobile molds, machines guides, camshaft, camshafts, etc.

We not only produce the UCI durometer with manual probes, but also the motorized probe with different application fields. Our UCI is really conformed with the international standard ASTM A1038-2017 and China national standard GB/T 34205-2017 from the indenter shape and testing forces, it has been exported to Germany, Japan, USA and other developed countries and regions.

Looking forward to your kind reply with interests soon

Thanks and best regards,

Tags: 2d measure machine, Hardness Measurement Solution, máy do 2d, máy do cmm, máy đo 3d, Sinowon