PCB Introduction and measurement solutions

PCB(Printed circuit boards) are used in all but the simplest electronic products. They are also used in some electrical products, such as passive switch boxes.

Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but now rarely used. PCBs require additional design effort to lay out the circuit, but manufacturing and assembly can be automated.

The flexible circuit board is a highly reliable and excellent flexible printed circuit board made of polyimide or polyester film. Referred to as soft board or FPC, it has the characteristics of high wiring density, light, weight and thin thickness.

Almost every electronic device, from electronic watches and calculators to computers, communication electronics, military weapon systems, as long as there are electronic components such as integrated circuits, in order to electrically interconnect them, use printed boards.

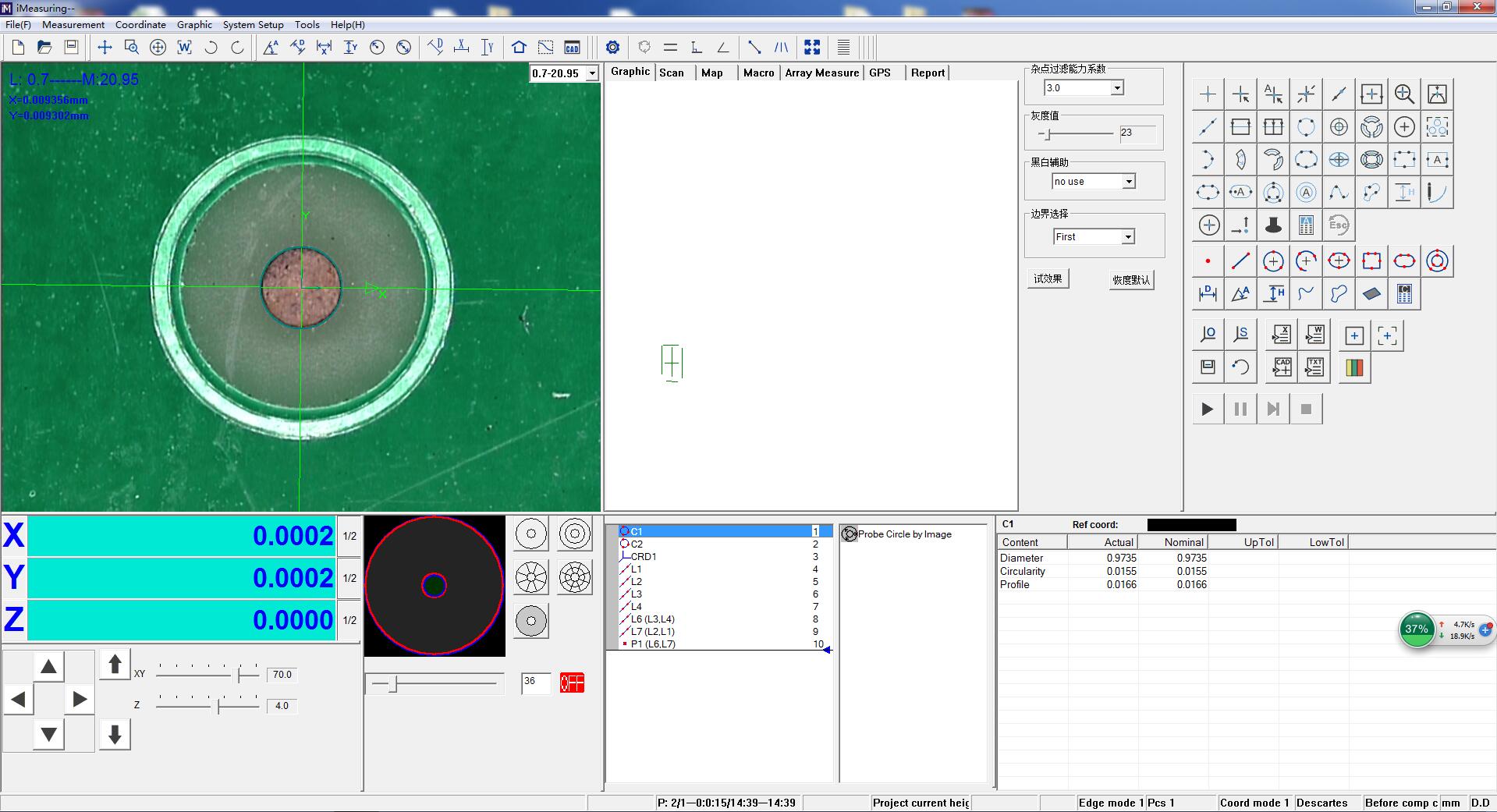

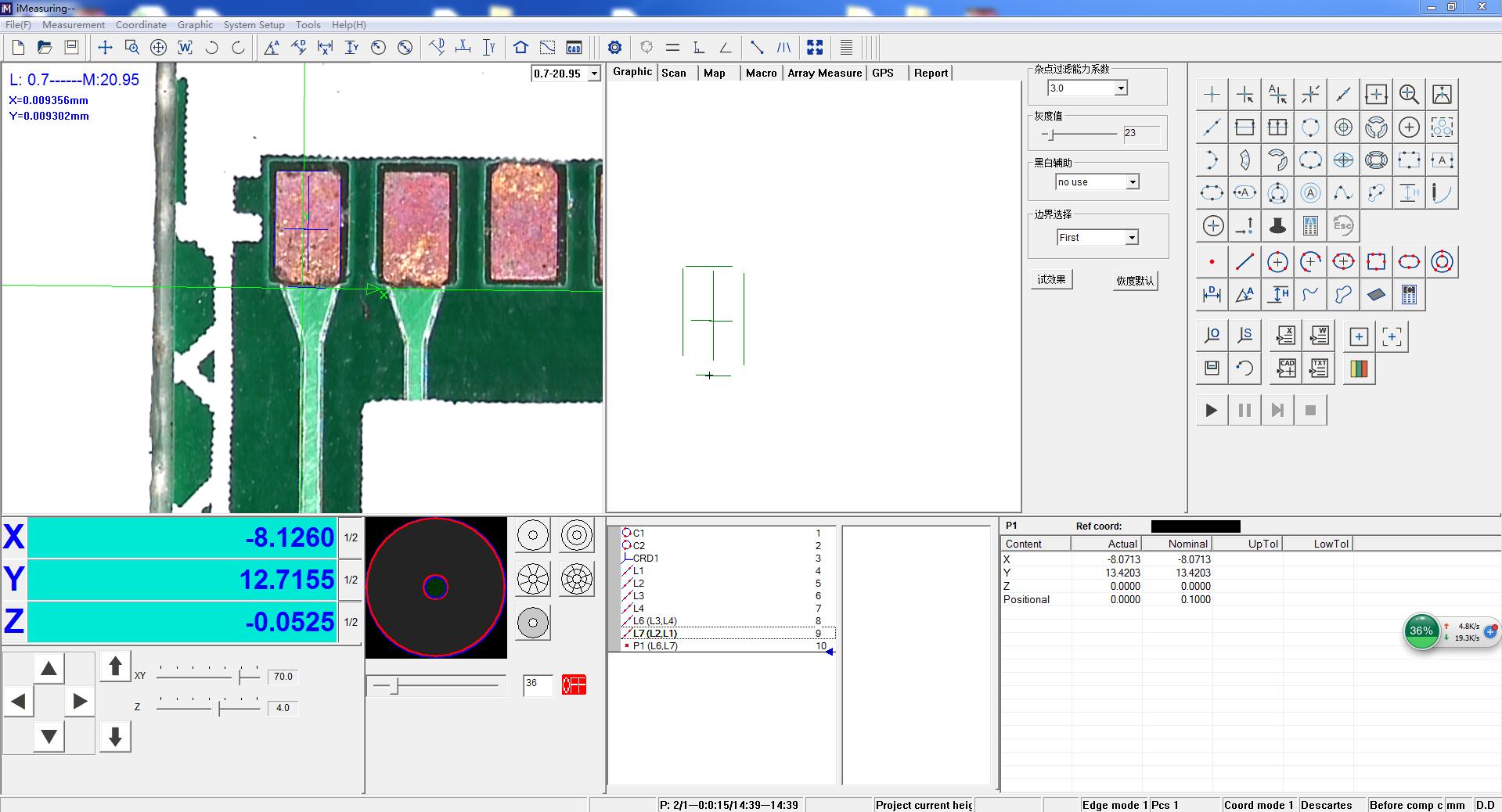

PCB Measuring geometric elements

PCB dimensions measure including width, height, pitch, pitch, thickness, arc, diameter, radius, groove, angle, R angle, etc.

PCB Measurement problem:

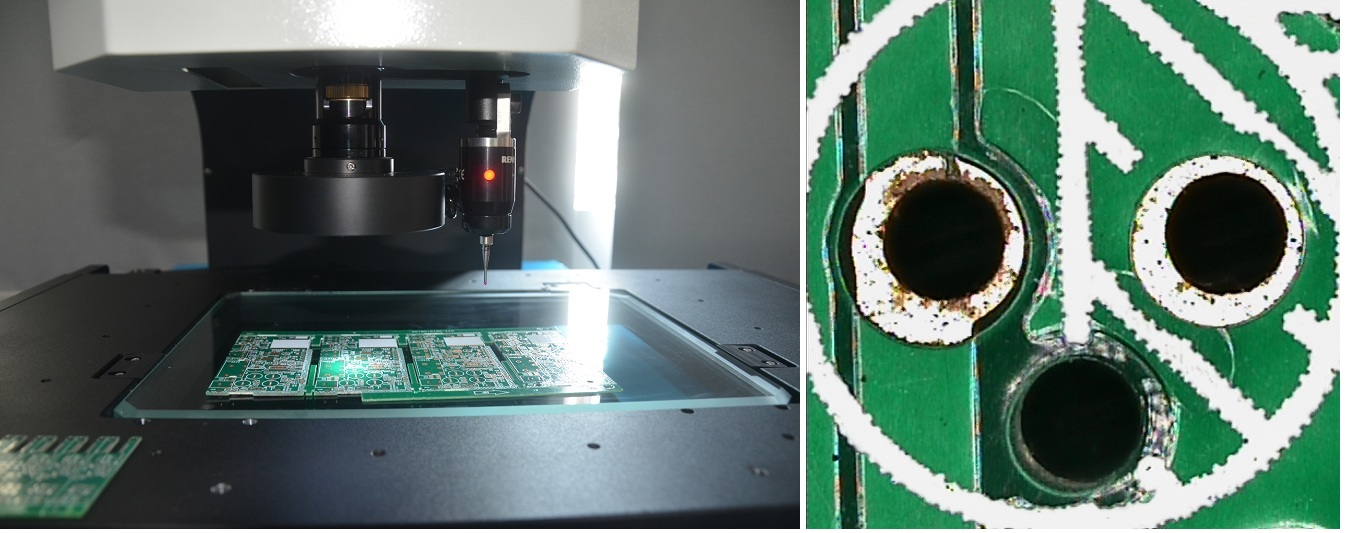

At present, some users begin to measure the PCB size by using a vision measuring machine, but most of the users still use the profile projector to directly measure. Because the comparator only measures a small range and measure the contour of the workpiece, and can not see the clear image on the surface of the workpiece. It has certain difficulties in the measurement of the upper surface, and most PCBs, such as flexible PCB boards, have relatively large output, soft materials, many types, and many sizes that need to be controlled. The projector can be used to measure operations such as non-photographing and printing. It caused great trouble for the measurement of follow-up statistics and quality control work.

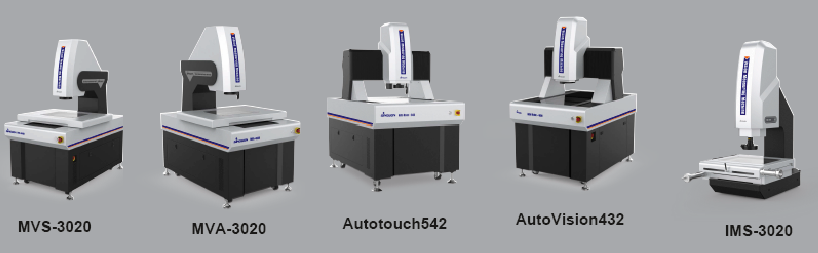

Sinowon Vision Measuring system

Therefore, Vision measuring machine has very obvious measurement advantages in the PCB industry because of their non-contact measurement and high measurement efficiency. It is a high-precision instrument that uses optical lenses and CCDs to acquire image data for geometric measurement.

Sinowon a manufacturer of high-quality image measuring instruments, Sinowon’s Auto Touch series of the automatic image measuring instruments have a variety of powerful functions and always have outstanding performance in the PCB field.

Sinowon Vision measuring machine Accuracy with fast measuring:

-Reduce manual operations

-Non-contact measurement

-Batch measurement

Maximum permissible error(MPE:Acc.to ISO10360)(L=measuring length in mm)

E1=(1.5+L/200)μm

E2=(1.9+L/150)μm

E3=(2.9+L/100)μm, at 20℃±1℃,0.5℃/h,0.5℃/m,Max,zoom,m≤10kg